Dale automation manufacture many different types of conveyors for transportation and handling of products as described in the conveying section.

Other product handling equipment is available from Dale and are listed below:-

- Automatic Oven/Prover loaders and unloaders for loading pans into and away from the oven or box type provers.

- Basket loaders for bread loading. Dale have a patented basket loader capable of loading 9000 loaves an hour using a single basket feed line.

- Basket stackers for stacking of baskets 10 to 12 high. Dale have a patented basket stacker capable of stacking 4500 baskets an hour.

- Basket De-elevating or elevating conveyors for transporting full or empty baskets from one factory floor level to another factory floor level. Each system is capable of handing 4500 baskets an hour.

- Bread Collating systems to eliminate labour and equipment from the packing lines. Each collator takes wrapped bread from the bagger slicers and transports it to a main body take away conveyor called the highway. The system conveys wrapped bread from the bagger slicer in single file long side leading to the collator pusher and counts 4 to 6 loaves through via counter proximity. The 4 to 6 loafs are then pushed sideways at 90 degrees short side leading the length of a loaf and gap. The system counts 4 to 6 more loaves through which ever number is programmed and pushes them sideways at 90 degrees to make a batch of 8 to 12 loaves. At this point the bread is pushed further onto a tilting conveyor and parked until the highway conveyor has a gap. Once a gap is sensed the tilting conveyor lowers downwards and drives the batch of bread onto the highway. There could be 4 to 6 bagger slicers feeding bread at any one time forming batches on the collator system. Bread is conveyed to the end of the conveyor and gently pushed into the awaiting crate.

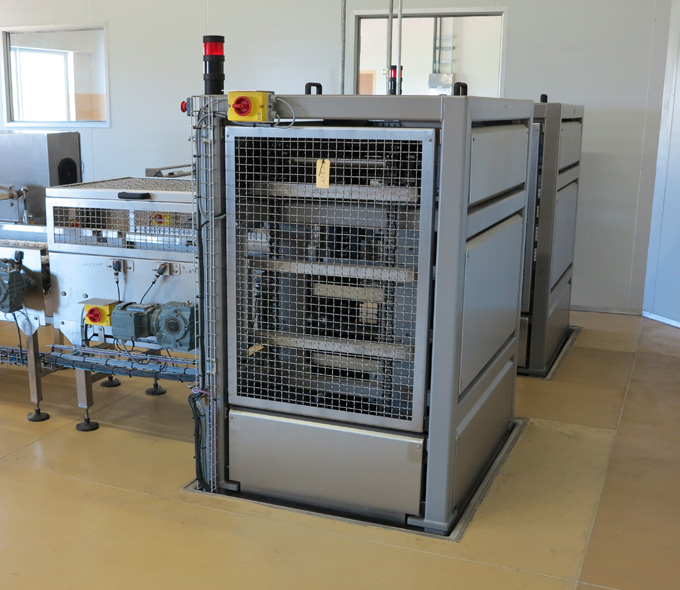

- Trash dump conveyor. Dale have designed a conveyor that accepts 3 to 4 baking pans or trays at any one time, it clamps the pans/trays and revolves them upside down 180 degrees to release trash, dough or bits that maybe left in the pan/tray. It then revolves back 180 degrees and allows the pans/trays to carry on in the system.